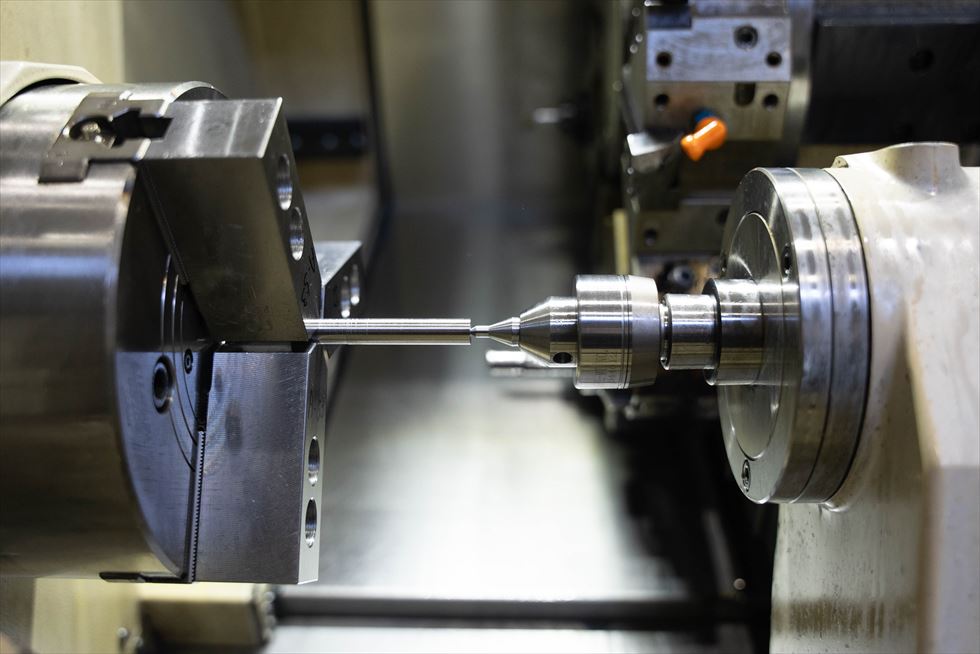

CUTTING PROCESSINGMachining of Difficult-to-Cut Materials Including Titanium, Stainless Steel, Composite Materials, and Nickel Alloys

We specialize in cutting aluminum and composite materials, and also process difficult-to-cut materials such as titanium, stainless steel, and nickel alloys.

Based on cutting data accumulated over many years, we determine optimal machining conditions to achieve high-precision part processing.

We respond to stringent needs across various industries, including the aerospace industry.

MICRON PROCESSINGMicron-Level Precision Large Part Processing with Skilled Technician Finishing

Our strength lies in precision machining within ±1μm units and finishing by skilled technicians, even for parts up to 2,000×4,000mm in size

Utilizing high-precision machining technology cultivated in the aerospace industry,We handle aerofoil structural parts, fuselage structural parts for aircraft, and various defense equipment components.

Combining milling by skilled technicians with state-of-the-art equipment such as 5-axis machining centers,Trusted by many customers for our ability to handle high degree of difficulty requests.

EQUIPMENTFMS and High-Precision Equipment

Introduced FMS (Flexible Manufacturing System),Equipped with high-speed, high-precision cutting-edge machining centers such as MAG3 (horizontal 5-axis) and VORTEX i-630V/6 (vertical 5-axis).

Capable of providing high-precision, high-quality products by utilizing abundant machining equipment for everything from large parts to minute components.

Thorough strict quality control using three-dimensional measuring instruments,Responding to diverse customer needs.

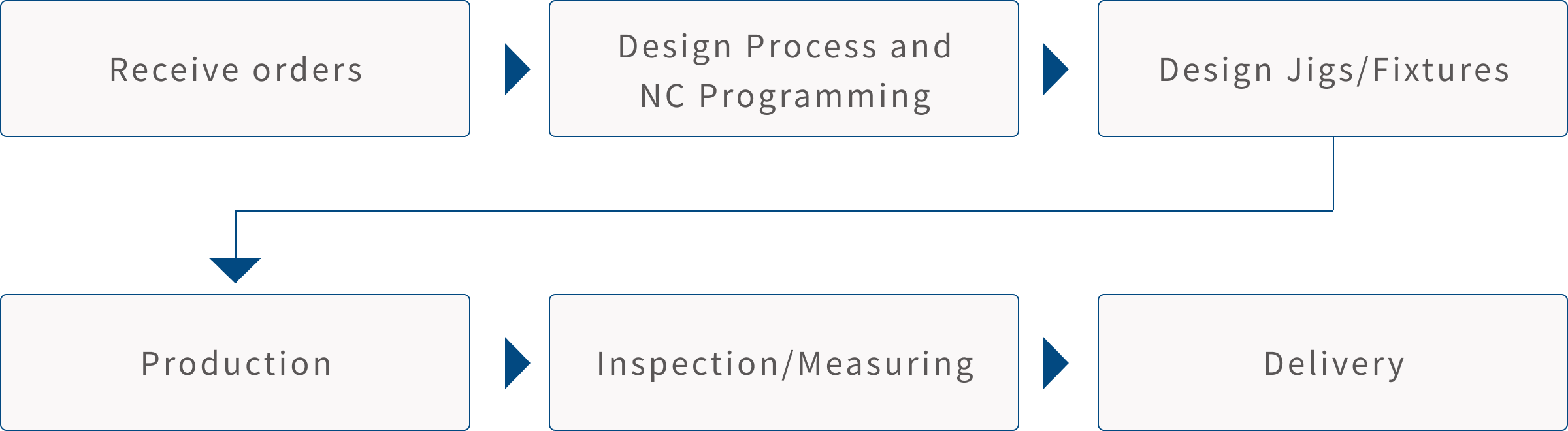

flowFlow to Delivery

From design to processing, we efficiently proceed to delivery through a smooth manufacturing flow utilizing 3D CAD

Manufacturing risks are suppressed by using 3D CAD simulation